We Make our own supplements

At G&G, we proudly uphold the ethos of our founder, David Gaiman. “Do it right.” This commitment is part of the reason why we make all our supplements from our own factory in the Sussex countryside. By staying in control of the production process, we can ensure that our customers know exactly what they’re getting when they choose to buy our supplements.

QUALITY COMES FIRST

Most importantly, we will never release a product that is not, to the best of our knowledge, as good as it can possibly be. It’s not always the quickest, easiest or most profitable road to take, and indeed may be one less travelled. It is, however, the one we set out on over fifty years ago, and we’ve never looked back. Quality comes first.

HIGH QUALITY INGREDIENTS

We work tirelessly to source only the best ingredients for our products. As a manufacturer, we have full control over where our ingredients come from and the quality checks that go in to making the best supplements for our customers.

The purity and sustainability of ingredients are of the utmost importance. If ingredients don’t meet these standards they will not be made. Sourcing good quality, non-GMO ingredients is a primary focus when formulating, and every ingredient we use comes to us with full traceability, right back to the soil or laboratory it was created in.

G&G focus on where raw materials come from, and investigate with extensive research and testing to verify ingredients are what they purport to be. Pathology, biotransformation, bioavailability, and interactions lead on to formulating the best complexes possible. We don’t just “make supplements”; we create them with care.

Staff at G&G have in-depth knowledge and experience of ingredients and how they respond to encapsulation, so can always find the best way to maintain a high quality and high purity without the need for excipients. There is no compromise in quality when sourcing ingredients, and at G&G we won’t settle for anything less than the best so that each stage of the manufacturing process is of the highest standard.

OUR SUSSEX FACTORY

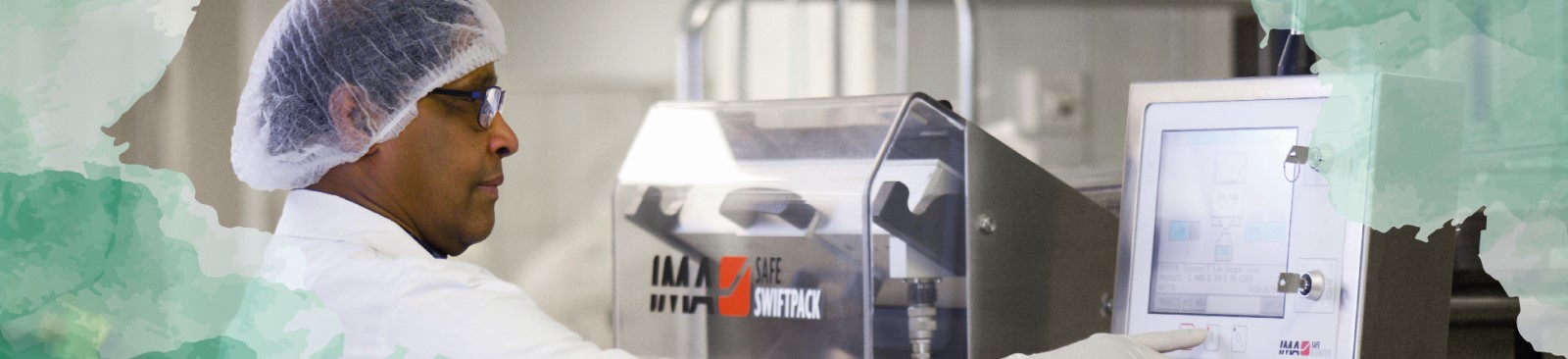

We manufacture our supplements in our very own ISO Class 8 cleanroom, based on-site at our headquarters in East Grinstead. The cleanroom has been designed to cater for the manufacturing of a diverse range of nutraceutical products for not only the G&G own brand products, but also our many contract customers, in keeping with their individual requirements.

We pride ourselves on our Class 8 cleanroom standards, which is one class higher than is necessary for supplement manufacture. Our cleaning procedures are so effective that when tested, our cleanroom in fact met air quality levels of an ISO Class 7 cleanroom. This is thanks to our effective air filtration system, which undergoes twenty complete air changes every hour.

Our semi-automatic encapsulation machines can produce over 3.5 million filled capsules per week, using our patented Trufil® technology. This process enables us to successfully encapsulate high-quality supplements without the inclusion of excipients and binders like magnesium stearate.

QUALITY CONTROL

G&G has 4 HACCP (Hazard analysis and critical control point) trained staff members and a HACCP system in place to guarantee the safety of products. Part of this system includes testing incoming herbal ingredients before use for microbial contamination by an independent lab to ensure they are safe and fit for human consumption and do not contain harmful bacteria.

Ingredients are also checked for other criteria and only get released for production if they conform to all specified criteria. We have a strict quality control procedure in place with our Quality Inspectors performing regular QC checks along the production line to ensure complete compliance to the product specification and accepted quality standards. Capsules that do not meet the standards are rejected. Documentation of every batch is kept for complete traceability and products are only released after each passes rigorous quality checks.

CERTIFICATIONS

G&G are proud to be certified by the MHRA (Medicines and Healthcare products Regulatory Agency), who validate our Good Manufacturing Practices (GMP) procedures. In addition, G&G are members of the Health Food Manufacturer’s Association, and are certified by the Soil Association for the manufacture of organic products, the Vegetarian Society for the production of vegan and vegetarian products. G&G have also passed inspections from a number of private and government agencies, including the Food and Drug Administration, Health Canada and Environmental Health.